Eco-friendly process for synthesizing organic materials developed for high-performance materials industry

Share

Until now, the production of materials from organic substances was only possible with the use of highly toxic solvents. A team led by chemist Miriam Unterlass, Professor at the University of Konstanz and Adjunct Principal Investigator at CeMM, has now developed a method for making organic substances suitable for use as high-performance materials in an eco-friendly and completely non-toxic way by generating them in only hot water. The study represents an important milestone in the green production of organic materials and thus also provides an important incentive to switch from inorganic to organic, renewable materials. Beside that the method is environmentally friendly, cost-effective, easy to use and also reduces the weight of the products. This could also benefit the production and weight of electronics.

Many of the products we use every day, such as rechargeable batteries and electronic materials, are made using inorganic substances - substances that are gradually becoming rarer on our planet. Chemists are looking for ways to replace inorganic materials with organic materials made of carbon, nitrogen, hydrogen or oxygen. To make these substances usable for the desired applications, highly toxic chemicals, so-called solvents, are still used today. This is precisely the problem that chemist Miriam Unterlass, Professor at the University of Konstanz and Adjunct Principal Investigator at the CeMM Research Center for Molecular Medicine of the Austrian Academy of Sciences, is addressing in her current study as part of her FWF START project. She explains, "Organic materials have many positive characteristics: they can be obtained from renewable raw materials, are environmentally friendly and, above all, are extremely lightweight. With our process, we can now also produce them and make them usable completely free of toxic solvents, very simply and inexpensively. In our current study, we have focused on the production of particularly porous materials that are needed for the manufacture of high-performance materials, especially in industry, for example for filter systems, membranes for fuel cells, but also for insulation in electronics."

The connection with water

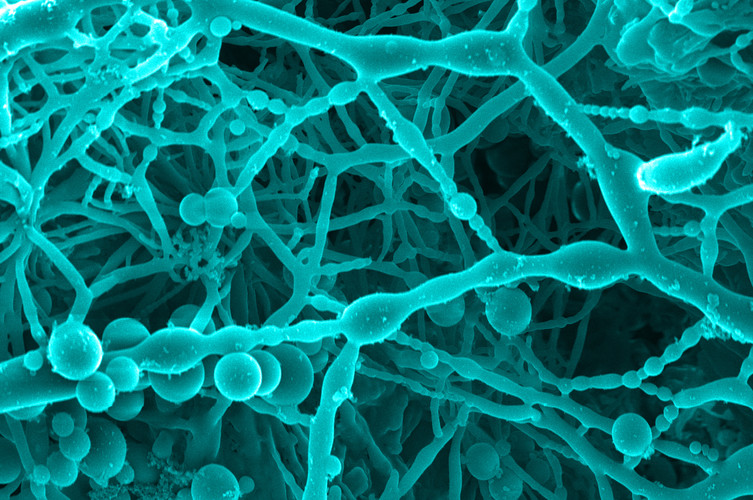

While inorganic substances such as salts are soluble in water, organic substances are apolar and do not dissolve with water in a conventional state. For their new method, study author Marianne Lahnsteiner, a PhD student in Unterlass' research group at CeMM, and project leader Miriam Unterlass heated water and found that it also changed its ability in the process. "By heating molecules containing only oxygen, hydrogen, nitrogen, and carbon in water between 180 and 250 degrees and under pressure, these molecules can bind. Depending on the temperature and duration of this process, we thus achieve different structures, which we have been able to explore in detail in hundreds of experiments," Unterlass said, "so we now know exactly which structures are created by which, at which temperature and processing time. The materials in our study were specifically developed as high-performance materials and are accordingly particularly temperature-stable and robust."

Screening, filtering, conducting

In one gram of the material produced by Lahnsteiner and Unterlass, there are an enormous 7250 mm3 of hollow space. Accordingly, it offers - depending on its shape - the perfect characteristics for filtering, seprarting and conducting molecules, and that at low weight. To make the structures created by the process more observable, the researchers collaborated with the research group of network scientist Jörg Menche, a professor at the University of Vienna and also an adjunct principal investigator at CeMM. Menche's research group used Artificial Intelligence to analyze the emerging structures and patterns based on the microscopy images. "With the help of Artificial Intelligence, we were able to quickly categorize a variety of emergent structures in a way that we know how to synthetically achieve these structures," Lahnsteiner said.

Green production with 25 percent initial cost savings

"Smog is a key sign of environmental pollution. Chemical processes are unfortunately partly responsible for its formation, through the use of toxic solvents. With our new method, we are creating an enormously important alternative for processing organic materials that does not require such toxic solvents at all. At the same time, very common elements are used instead of rare ones," Unterlass said. "In addition, the process is very cost-effective. Using water versus toxic solvents in the production of porous materials saves about 25 percent of the cost. And we don't produce pollutants."

Interdisciplinarity at CeMM

Around 140 researchers from 49 nations worldwide conduct research at the CeMM Research Center for Molecular Medicine. Interdisciplinarity is an important core element of successful research. Scientists from biology, medicine, bioinformatics, chemistry, and physics thus not only make an important contribution to biomedical research for improving the diagnosis and therapy of diseases, but also conduct basic research at the highest level.

The study is part of the FWF START project "Hydrothermal to functional organic framework structures.

The article "Hydrothermal Polymerization of Porous Aromatic Polyimide Networks and Machine Learning-Assisted Computational Morphology Evolution Interpretation" appeared in the Royal Society of Chemistry's peer-reviewed Journal of Materials Chemistry A on September 7, 2021 DOI: 10.1039/D1TA01253C.

Authors: Marianne Lahnsteiner, Michael Caldera, Hipassia M. Moura, D. Alonso Cerrón-Infantes, Jérôme Roeser, Thomas Konegger, Arne Thomas, Jörg Menche, and Miriam M. Unterlass.

Funding: This study was funded by grant START Y1037-N38 from the Austrian Science Fund (FWF).